- Comprehensive Service Solution Provider

- alina@suntechprinter.com

Suntech Printing Technology

Faster More accurate More efficient Smarter

ST-S5400 One pass printer

Assembly line printing, flexible application, no need to worry about urgent orders or short orders, truly printing from one sheet.

1. No plate making is required, one piece is printed and picked up immediately, saving labor and plate making and other process costs;

2. Assembly line operation, support for multi-task printing, variable data printing, high efficiency and strong functions;

3. Ricoh nozzle, all-steel nozzle, long life, strong wear resistance, variable ink drop technology, high printing quality;

4. Variable ink drop technology prints more delicate and layered images, saving 30% of ink. Multiple colors and gradient colors can be easily printed at one time, with bright colors and realistic patterns;

5. No offset or positioning, accuracy up to 1200dpi, fastest 30 meters in 1 minute;

Product attributes

| Machine type | One pass printer |

| Nozzle | Ricoh GEN5 |

| Model | ST-S5400 |

| Accuracy | 1200DPI, 900DPI, 600DPI |

| Curing system | UV LED lamp curing |

| Color mode | 4 colors/white |

| Equipment size | 2800*1200*1700mm |

| Ink supply system | 1.5 liter capacity, automatic ink shortage alarm, ink can be added without stopping the machine, double negative pressure ink supply system |

| Wide width of actual printing | 54mm, 108mm, 162mm, 216mm |

| Input power | Maximum power 5KW; AC 220V (±10%) > 15A; 50Hz-60Hz |

| Printing media | Glass, acrylic, ceramic tiles, metal plates, PVC boards, cardboard, wood boards, leather, etc. |

| Working environment | The temperature is 18°C-50°C and the humidity is 30%~70% which can effectively control static electricity and ensure the quality of printed pictures |

| RIP software | Photoprint, colorgate |

| Suction platform | Suction guide tape to adapt to different materials |

| Safety certification | CE certification, SGS certification, MSDS certification |

| Total weight | 800kg |

Features

Print Pioneer

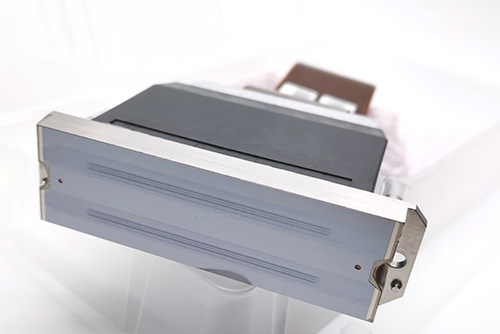

Industrial Ricoh G5 print head, all-steel nozzle, strong wear resistance and long life.

- Variable droplet technology minimizes graininess with minimum 7.0 pl droplets for high print quality.

- Supports up to 1200dpi and has flash spray function to keep the nozzle in good working condition

- A variety of printing modes including white color, varnish, and embossing to meet various job needs

Plasma pretreatment

Control the details to make the product more outstanding

--The plasma pretreatment device cleans and activates the product surface, improves the product surface properties, and makes printing more perfect.

--The self-developed feeding belt has a high-precision automatic correction function and an air suction system to ensure that printing materials are transported more stably.

--The use of PLC control makes it more reliable and more flexible to use.

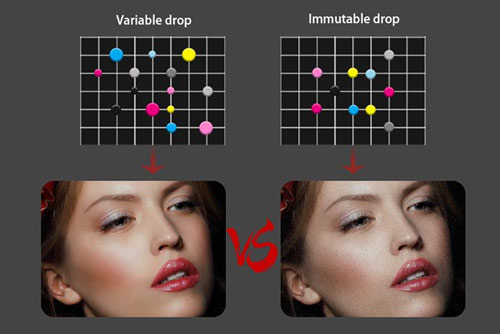

Variable droplet technology

The imported Ricoh printhead we use has very powerful variable ink droplet technology.

-When the printer is working, it can intelligently change the size of the ink droplets

-Precise control of image color not only efficiently produces printing effects, but also saves ink usage

-Rich printing layering makes the picture more delicate and the printing quality higher

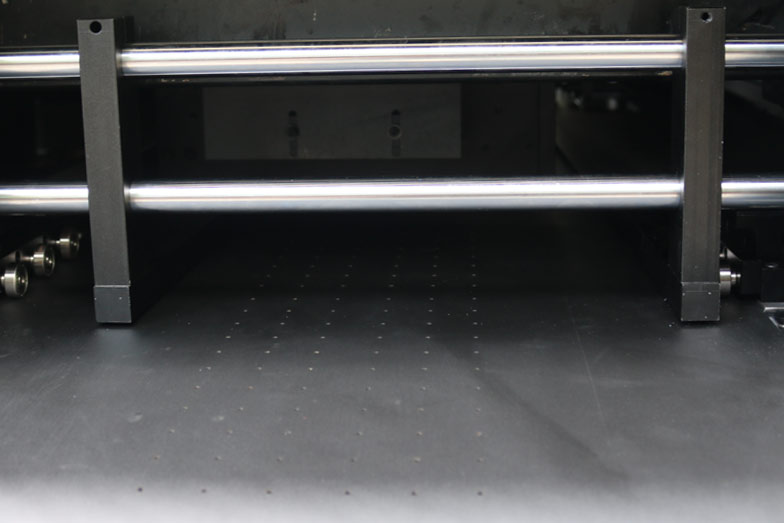

Suction wear-resistant guide belt

We use self-developed feed suction and wear-resistant belts with high-precision, fully automatic and correction functions.

-The suction area and air volume can be adjusted at will, and can absorb different materials to ensure the stability of feeding.

-Reasonable layout of air suction holes and precise positioning improve product production efficiency

-The belt is made of high-quality A+ raw materials combined with new fiber material PU50AE, with a strength of 20N/mm and strong wear resistance and tensile strength.

It is 4 times that of ordinary polyester guide tape, good equipment, every detail is

Dual negative pressure cartridge system

Our carefully designed dual negative pressure cartridge system

-Automatically balance negative pressure to ensure inkjet stability and smoother inkjet

-Backflow device ensures the safety of the negative pressure system and saves ink usage.

-Automatic alarm for lack of ink, and ink can be added without stopping the machine

-The secondary ink supply device effectively controls the output and double high-density filtration to ensure smooth ink and not easy to clog.

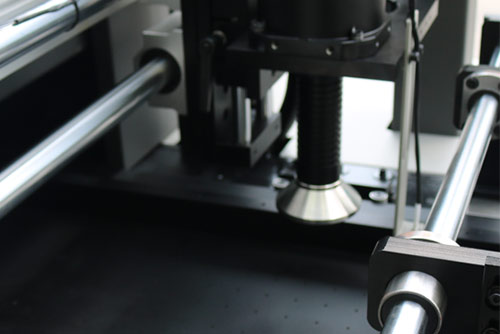

X, Y, Z axis servo motor

Servo motor drive, accurate and reliable

-Equipped with automatic height measurement and positioning systems to ensure high-efficiency printing production

- Independent servo motor drive, precise control

-Automatic error correction, when movement deviation occurs, the starting point of bilateral printing is automatically corrected.

The servo motor is matched with an imported screw rod to ensure movement accuracy.

Applications

Products widely used Glass, acrylic, ceramic tiles, metal plates, PVC boards, cardboard, wooden boards, leather, inkjet cloth, wallpaper, car stickers, stationery, gifts, cosmetics, lunch boxes, etc.

Product advantages

Perfect after-sales service

- After-sales group of more than 10 people

- Professional technical after-sales team, 24-hour online service

- Support global door-to-door service.

Quality assurance

-

The designer has 20 years of experience,

-

Product quality assurance and customer customization are provided.

Imported accessories are used inside the equipment Standardized production operation process

Sold overseas

- All machines pass CE FDA certificate

-

With the United States, Australia, Europe, and Southeast Asia

Waiting for cooperation with customers in more than 100 countries and regions