- Comprehensive Service Solution Provider

- alina@suntechprinter.com

Suntech Printing Technology

Faster More accurate More efficient Smarter

ST-C300 Heat transfer printer

1. The integrated mold platform prints more smoothly, and the 3-stage heating has good ink absorption;

2. The silent guide rail makes no noise and makes printing more stable;

3. Intelligent digital temperature control system makes it easier to observe the temperature in real time and operate more conveniently;

4. The intelligent ink system provides intelligent alarm and ink refilling, making it more user-friendly;

5. High-precision servo motor, high precision, small error and clearer printing;

Product attributes

| Machine type | UV crystal label printer |

| Print head | Ricoh fifth generation/sixth generation |

| Model | ST-C300 |

| Accuracy | 1800DPI, 1200DPI, 900DPI, 600DPI |

| Maximum printing area | 3200*2000mm |

| Cure system | UV LED lamp curing |

| Ink configuration | 4 colors/6 colors/white/varnish optional/ |

| Device size | 5100*2850*1450mm |

| Print length | 0~100mm |

| Equipment weight | 1100KG |

| Equipment power | 7.5KW |

| RIP software | photoprint |

| Catridge capacity | 1.5 liter capacity, automatic ink shortage alarm, ink can be added without stopping the machine |

| Power supply voltage | AC 220V (±10%)> 15A; 50Hz-60Hz |

| Device Certification | CE/ROHS/SGS |

Features

Print Pioneer

Industrial Ricoh G5 print head, all-steel nozzle, strong wear resistance and long life.

- Variable droplet technology minimizes graininess with minimum 7.0 pl droplets for high print quality.

- Supports up to 1200dpi and has flash spray function to keep the nozzle in good working condition

- A variety of printing modes including white color, varnish, and embossing to meet various job needs

Dual Y-axis servo motor

Two-axis synchronous rotation, accurate and reliable

-Equipped with automatic height measurement and positioning systems to ensure high-efficiency printing production

- Dual Y-axis independent servo motor drive, synchronous rotation, precise control

-Automatic error correction. When there is a deviation in the movement, the starting point of bilateral printing is automatically corrected to ensure the synchronization of the movement of the screw rods on both sides.

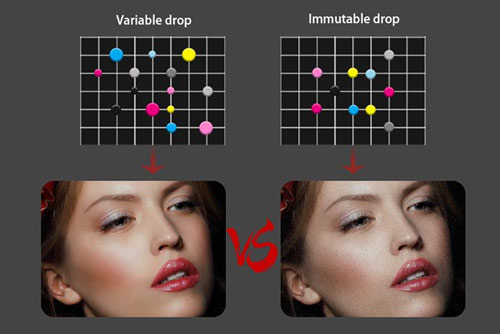

Variable droplet technology

The imported Ricoh printhead we use has very powerful variable ink droplet technology.

-When the printer is working, it can intelligently change the size of the ink droplets

-Precise control of image color not only efficiently produces printing effects, but also saves ink usage

-Rich printing layering makes the picture more delicate and the printing quality higher

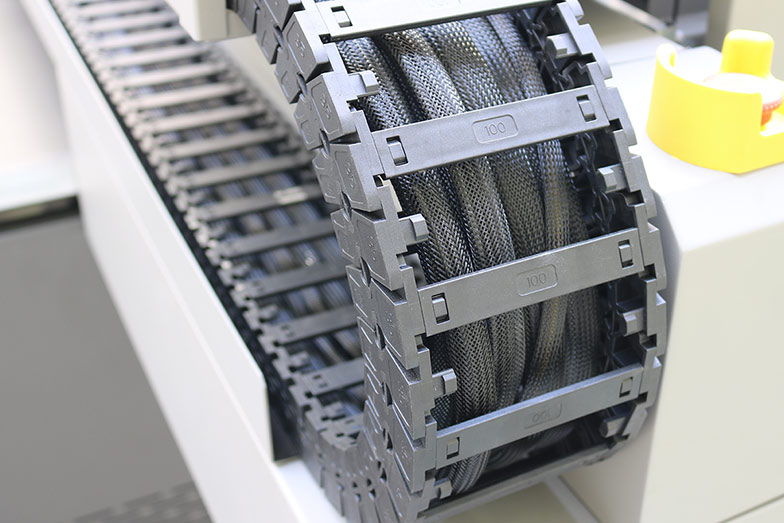

German silent IGUS drag chain

Our equipment adopts German IGUS drag chain

-Effectively prevent cables from breaking after being pulled, ensuring the safety and standardization of production and extending cable life.

-Using Japanese THK guide rails, the equipment runs more smoothly and has a long service life.

-The combination of guide rails and silence makes the equipment more stable during high-speed movement.

It can also maintain low noise and provide a quiet working environment.

Dual negative pressure cartridge system

Our carefully designed dual negative pressure cartridge system

-Automatically balance negative pressure to ensure inkjet stability and smoother inkjet

-Backflow device ensures the safety of the negative pressure system and saves ink usage.

-Automatic alarm for lack of ink, and ink can be added without stopping the machine

-The secondary ink supply device effectively controls the output and double high-density filtration to ensure smooth ink and not easy to clog.

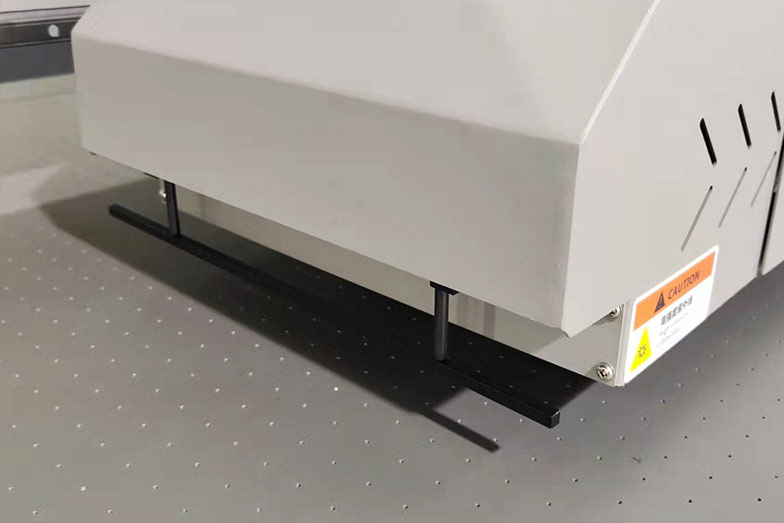

Photoelectric induction anti-collision system

-The equipment is equipped with infrared photoelectric induction system

-The photoelectric sensor will automatically detect whether the product is placed and provide an alarm function.

-Can be equipped with anti-collision device to protect the print head and user safety

-The equipment platform has a suction area and air volume that can be adjusted at will, and can absorb different materials.

,Hard oxidation adsorption platform The platform has high surface hardness, corrosion resistance and long service life.

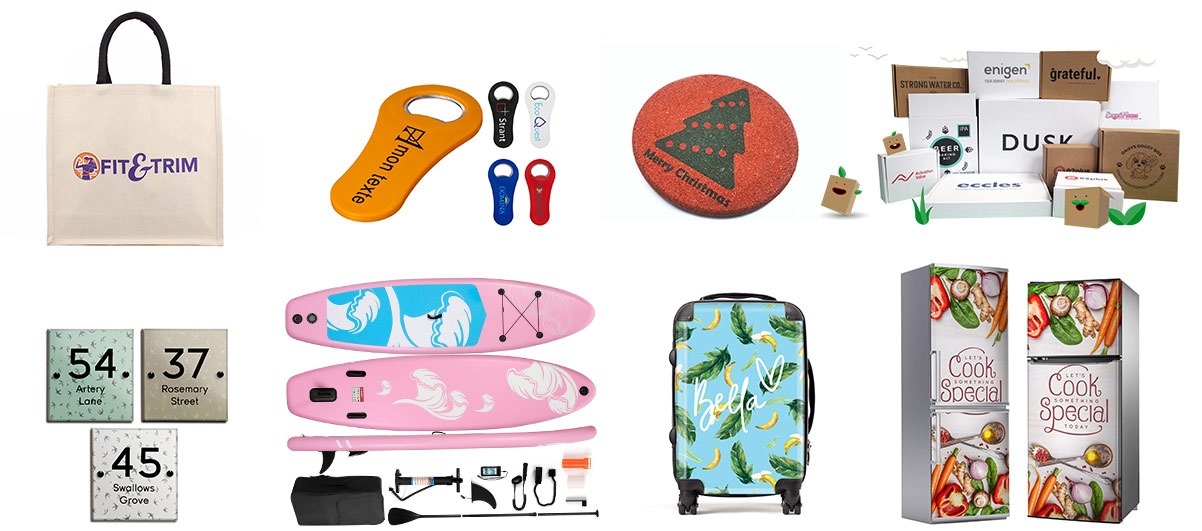

Applications

Products widely used Glass, acrylic, ceramic tiles, metal plates, PVC boards, cardboard, wood boards, leather, inkjet cloth, wallpaper, car stickers, etc.

Product advantages

Perfect after-sales service

- After-sales group of more than 10 people

- Professional technical after-sales team, 24-hour online service

- Support global door-to-door service.

Quality assurance

-

The designer has 20 years of experience,

-

Product quality assurance and customer customization are provided.

Imported accessories are used inside the equipment Standardized production operation process

Sold overseas

- All machines pass CE FDA certificate

-

With the United States, Australia, Europe, and Southeast Asia

Waiting for cooperation with customers in more than 100 countries and regions