Background

The client specializes in high-end interior decoration materials with diverse design requirements. They demand realistic and natural patterns on tile surfaces, often with intricate textures.

Pain Points

- Traditional spray printing struggles with poor adhesion on tile surfaces and lacks detail clarity.

- High expectations for accurate reproduction of complex textures and color fidelity.

- Need for batch production while maintaining consistency across every tile.

Solution

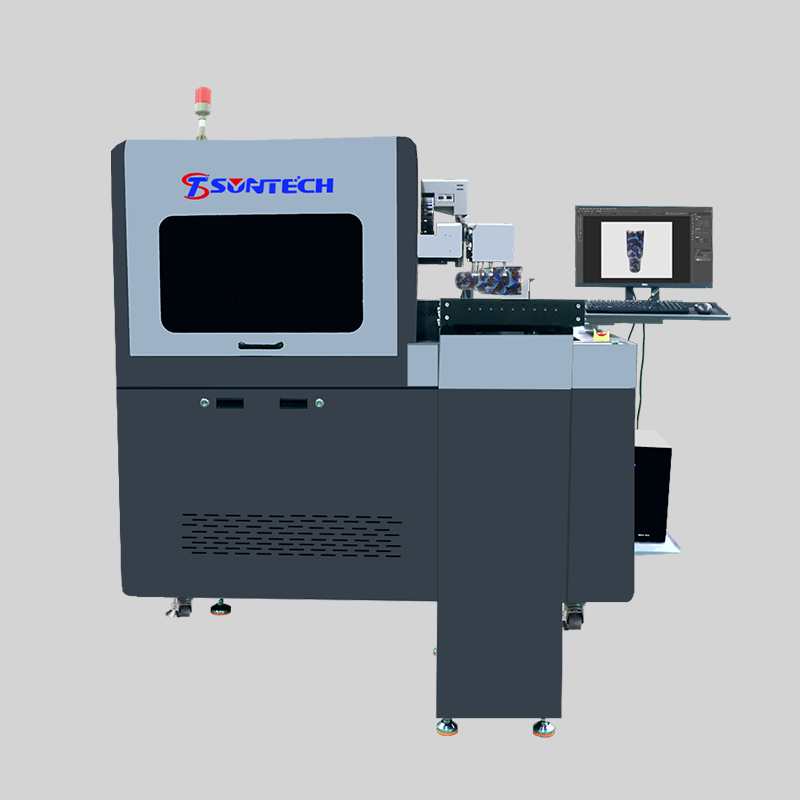

- UV flatbed printing technology was used to print directly on tile surfaces, enhancing ink adhesion.

- Multi-pass printing with color, white ink, and varnish layers was employed to simulate realistic marble textures with 3D effects and no color deviation.

- A precise color management system was implemented to ensure color consistency across batches.

Results

- Printed tile background walls featured highly realistic and detailed patterns, earning strong client approval.

- Product pricing was approximately 40% lower than imported tiles, significantly boosting sales.

- Improved production efficiency enabled fulfillment of large-scale orders.