Understanding the Core Advantages of a UV Digital Inkjet Printer

The Physics Behind UV Curing Technology

UV curing ink contains photoinitiators and monomers that react when exposed to ultraviolet light. Rather than evaporating into the air like solvent-based inks, UV ink undergoes photopolymerization. This forms a hard layer which becomes strongly bonded with the printing surface.

There is virtually no drying time because of this reaction taking place within split seconds thus reducing instances of smudging as well as allowing for handling immediately after printing has been completed on it . Its chemistry allows for high levels of detail , sharpness accompanied by resistance to weathering ; attributes much sought after in commercial besides industrial applications .

The Influence of UV Ink Formulations on Print Quality

The UV inks jetted thru a UV Digital Inkjet Printer have been formulated for wide performance parameters. Excellent adhesion, high color density, chemical and scratch resistance are some of the specific properties delivered by these inks. Since there is no absorption into any substrate to break down the image, crisp images remain.

As an added benefit toward sustainability initiatives that still allow top levels of performance from the product itself, UV inks contain lower amounts of volatile organic compounds (VOCs) in their formulation.

Durability and Longevity in Harsh Conditions

A primary reason that a UV Digital Inkjet Printer ranks high on the preference list among various industries is because of the extreme durability of UV prints, which can be defined as being resistant to scratching and fading or moisture. The fact remains that they could be placed outdoors or in high-traffic conditions without any significant degradation.

The application markets demand durability-from vehicle wraps and construction signage to product labels and industrial control panels. UV output has proven itself up to such stringent demands.

The Expanding Applications of UV Digital Inkjet Printer Technology

The versatility of a UV Digital Inkjet Printer allows it to serve a wide range of sectors. From advertising companies to industrial manufacturers, the ability to print directly on various surfaces has triggered new business models and creative product designs.

Advertising and Large-Format Displays

UV clarity, UV fade resistance, and UV vivid color make a great deal of difference in billboards and outdoor signage, exhibition graphics or promotional panels. The instant curing is an added protection from weather that maintains graphic detail for long-term display.

Advertising companies can eliminate production steps to save on costs since materials such as foam board, acrylic, PVC or composite panel can be printed directly with a UV printer.

Customized Product Decoration and Personalization

Personalization is one of the strongest growth areas influenced by UV Digital Inkjet Printer technology. The ability to print custom designs on small batches or even individual objects has changed the economics of on-demand production.

Popular examples include personalized gifts, smartphone cases, promotional items, stationery, awards, plaques and household décor. Businesses can offer customized prints with short lead times and high margins.

Packaging and Labeling Applications

Packaging companies mostly UV printers for both functional andw also aesthetical reasons. The text is sharper, more color accurateandand has great adhesion to materials likemetal,l coated paper PET , PP.

Cosmetics, phar labeling maceuticals beverages consumer goods UV because inks are smudge proof chemica resistant l . Highres barcodes QR codes scan friendly because prints maintain edge sharpness.

Industrial and Manufacturing Uses

Besides visual communication, UV Digital Inkjet Printer is involved in a critical industrial manufacturing process. More important than its display printing capabilities on metal, glass, ceramics and even flexible films; functional printing includes:

- Branding directly to substrate

- Marking electronic components

- Printing circuit patterns

- Industrial labels & safety markings

The adhesion strength and reliability make UV printing suitable for factory environments where traditional printing or labeling methods might fail.

Why Businesses Are Choosing UV Digital Inkjet Printers Over Traditional Systems

The shift toward UV technology is not simply a trend; it is a strategic response to changing industry requirements. Businesses choose UV Digital Inkjet Printers because they offer real performance and economic benefits.

High-Speed Production With Immediate Handling

Conventional printing needs drying time. UV has no drying time because curing is instant. There are no more bottlenecks in waiting for sheets to dry. Printing can be continued and completed within a smaller workspace, with minimal working space required to complete the job companies achieve all the benefits of reduced lead times-increased efficiency enhanced throughput.

That makes this advantage even more significant for high-volume packaging industrial marking promotional product businesses.

Superior Print Resolution and Color Vibrancy

More often, the modern UV Digital Inkjet Printers are of higher resolution than the traditional solvent printers. High-density color printing with very fine droplet control is capable of delivering photorealistic output, sharp text as well as smooth gradients.

In such industries where branding and visual impact happen to be key areas, it becomes an aspect beyond value that consistent print quality can be maintained on different substrates.

Broad Compatibility With Diverse Materials

Energy Efficiency and Reduced Environmental Impact

UV LED lamps consume significantly less energy than traditional mercury lamps or solvent drying systems. They also reduce emissions due to lower VOC content in UV inks.

For companies pursuing greener production, UV printing helps support sustainability initiatives without sacrificing performance.

Exploring the Workflow Efficiency of a UV Digital Inkjet Printer

Workflow optimization is a priority for modern production facilities. UV printers enhance workflow efficiency through automation, predictable output and simplified processes.

Simplified Pre-Press Requirements

There is very little setup involved in UV printing compared to offset or screen printing. No plates, no meshes, nothing at all by way of a long preparation process. Artwork is simply loaded through a digital workflow and the operator can start the press run.

This makes small batches-or even single one-off prints-viable to pursue economically. That enables business models based around customized goods, prototypes and short runs of product lines.

Repeatability and Color Consistency

Color is one important aspect of quality. The UV Digital Inkjet Printer delivers consistent ink laydown and curing to support the stable reproduction of color-accurate prints on different runs or even materials.

This has made the machine popular in industries where work involves a lot of branding, hence printing with consistent colors.

Integration With Automation and Smart Manufacturing

UV printers are integrated with vision systems, conveyors, automated feeders and robotic arms. Industrial UV printing is largely responsible for creating opportunities in FULLY AUTOMATED industrial printing lines.

Automatic height detection & positioning plus smart curing system make the production faster and more reliable.

Challenges and Considerations When Implementing UV Digital Inkjet Printers

While UV Digital Inkjet Printers offer many advantages, proper planning is essential for optimal implementation.

Understanding Material Surface Energy and Adhesion

Not all materials have the same surface energy. Certain plastics, coated metals or untreated surfaces may require pre-treatment such as corona treatment, flame treatment or primer application.

Understanding adhesion requirements ensures long-term durability and prevents print failures.

Selecting Appropriate UV Ink Formulations

Different applications demand different ink properties. Highly flexible inks for soft materials and hard inks to be applied on rigid substrates. Outdoor applications of high–resistant inks.

Matching the ink chemistry with the substrate properties is a crucial step in achieving professional results.

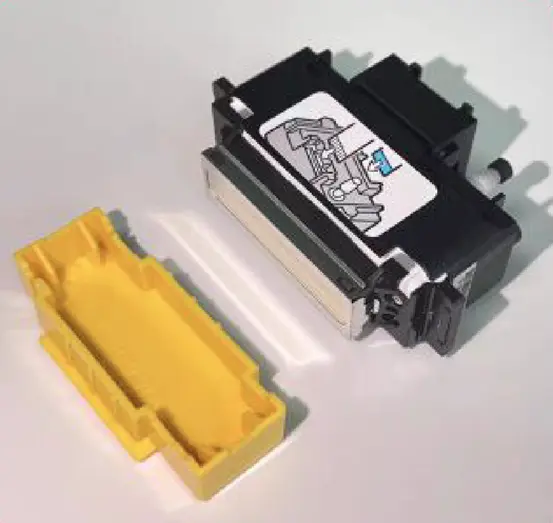

Maintenance Requirements and Machine Care

UV printers require regular cleaning of printheads and periodic calibration. Maintaining humidity levels, handling ink properly and minimizing dust exposure will extend equipment lifespan and preserve quality.

Cost Considerations and Return on Investment

UV Digital Inkjet Printers can have higher initial costs, but the long-term value comes from productivity, substrate versatility and reduced waste.

A detailed cost-benefit analysis helps businesses determine the best model for their production scale and quality expectations.

The Future of Printing: How UV Digital Inkjet Printers Will Shape the Industry

The trajectory of UV printing points toward even greater adoption as technology becomes more advanced and more accessible. Several trends are accelerating its future growth.

Advancements in LED UV Technology

More efficient LED lamps reduce heat, consume less energy and extend operational lifespan. This enables printing on heat-sensitive materials and lowers maintenance costs.

The continuing development of LED curing systems will strengthen the competitiveness of UV printers.

Expanding Industrial Applications Through Functional Printing

Future UV printers may not just decorate objects—they may create functional surfaces such as conductive circuits, protective coatings, antimicrobial layers or sensor-integrated patterns.

This opens opportunities in electronics, automotive, aerospace and medical industries.

Integration of Artificial Intelligence and Smart Monitoring

AI-driven print management systems can optimize color profiles, detect anomalies, predict maintenance needs and ensure consistent output.

Smart monitoring increases reliability and reduces downtime, making UV Digital Inkjet Printers even more efficient in industrial environments.

Growing Demand for Personalization and On-Demand Manufacturing

Consumer expectations for personalized, short-run and high-quality custom products are increasing. UV printing supports this demand with flexibility, rapid prototyping and scalable batch sizes.

E-commerce, interior décor and consumer electronics will continue to drive UV printer adoption.

Conclusion: Why the UV Digital Inkjet Printer Represents the Future of High-Performance Printing

UV Digital Inkjet Printer cures instantly, delivers high-definition images, proves compatible with a long list of materials and is basically known as versatile. It has therefore either directly or indirectly through finished products affected almost every sector relying on hardcore high-precision printing; advertising signage to industrial manufacturing and product customization.

This is among the most progressive forms of printing technology in that it permits quick production runs on a wide variety of different stock materials with an environmentally friendly process. As work continues to develop and improve inks, LED curing systems, automation as well as artificial intelligence(AI ) integration , UV Digital Inkjet Printer will become one main leading new generation industrial print solution .