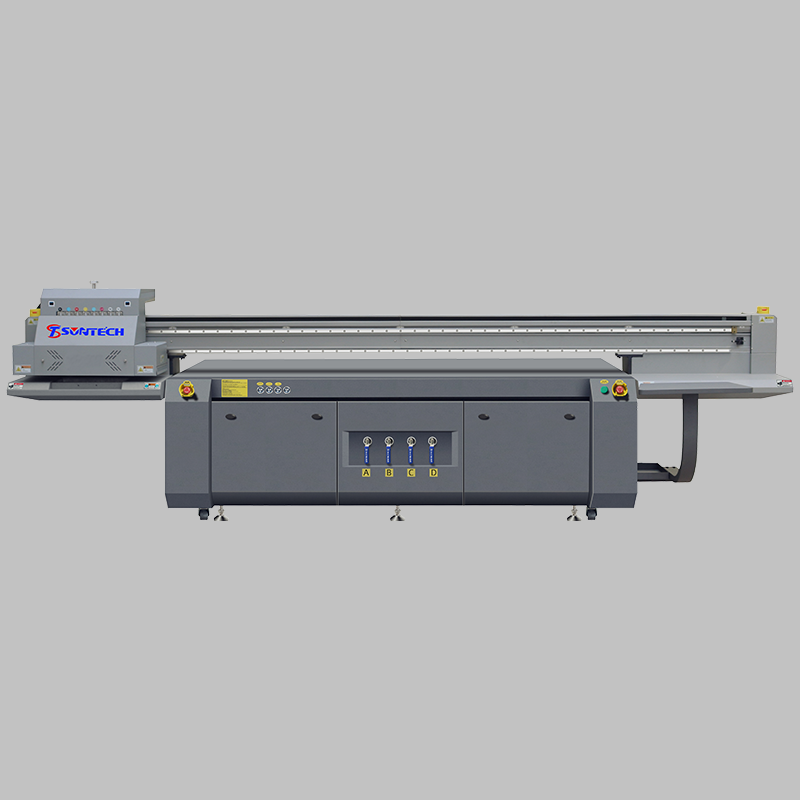

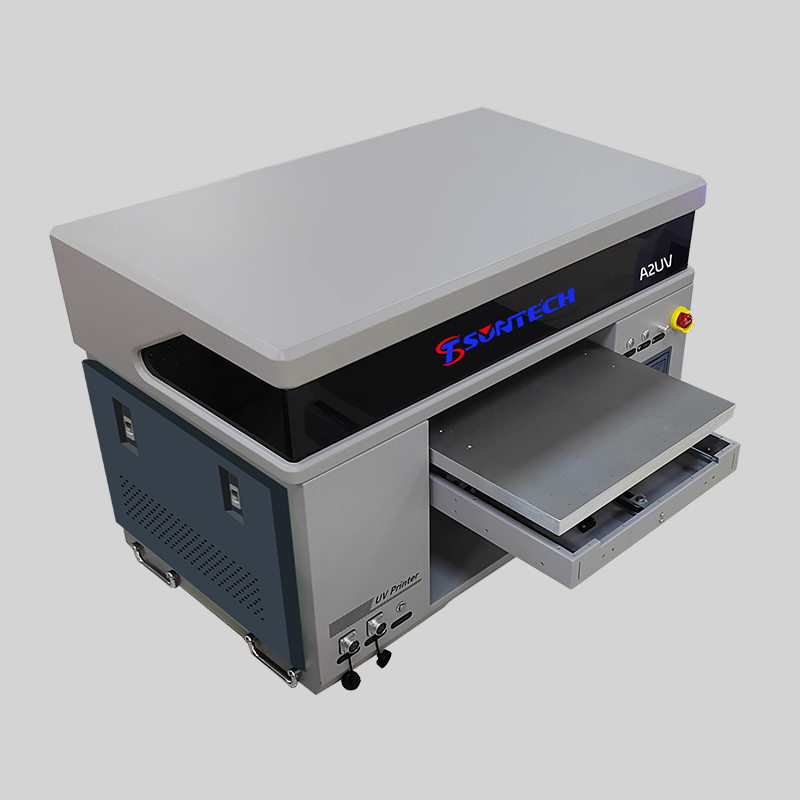

4060UV Flatbed Printer – Breaking Traditional Printing Methods, Enhancing Productivity and Quality

In the digital printing industry, as technology continues to advance, the demands on printer performance have become increasingly stringent. The 4060UV flatbed printer, with its exceptional print quality and versatility, has become a leader in the industry. Whether it’s flatbed printing or roll-to-roll printing, this printer delivers precise and fast results to meet a variety of needs.

The Epson I1600 printhead used in the 4060UV further enhances both print quality and stability, offering:

- High Precision: Ensures detailed and sharp prints even on complex designs.

- Enhanced Stability: Reliable performance over long printing runs, minimizing downtime and maintenance.

- Versatility: Capable of handling various materials and applications, from rigid surfaces to flexible substrates.

- With its advanced technology and superior functionality, the 4060UV sets a new standard for productivity and quality in digital printing.

Multi-Function Printing to Meet Diverse Needs

The 4060UV flatbed printer offers dual functionality with both flatbed printing and roll-to-roll printing, delivering exceptional performance on both rigid materials and roll substrates.

- Flatbed Printing: It supports a wide range of materials such as wood, metal, glass, acrylic, and other flat surfaces. The printer can even handle printing on 3D-shaped objects, providing unprecedented flexibility and broad application potential.

- Roll-to-Roll Printing: Capable of continuous printing on large-format roll materials, greatly enhancing production efficiency and continuity. It is suitable for applications such as glass, leather, acrylic, and other flexible materials.

Whether for small-batch customized production or large-scale industrial manufacturing, the 4060UV effortlessly meets the demands while maintaining exceptional print quality. This versatility makes it ideal for industries requiring both high-quality custom prints and high-volume production.

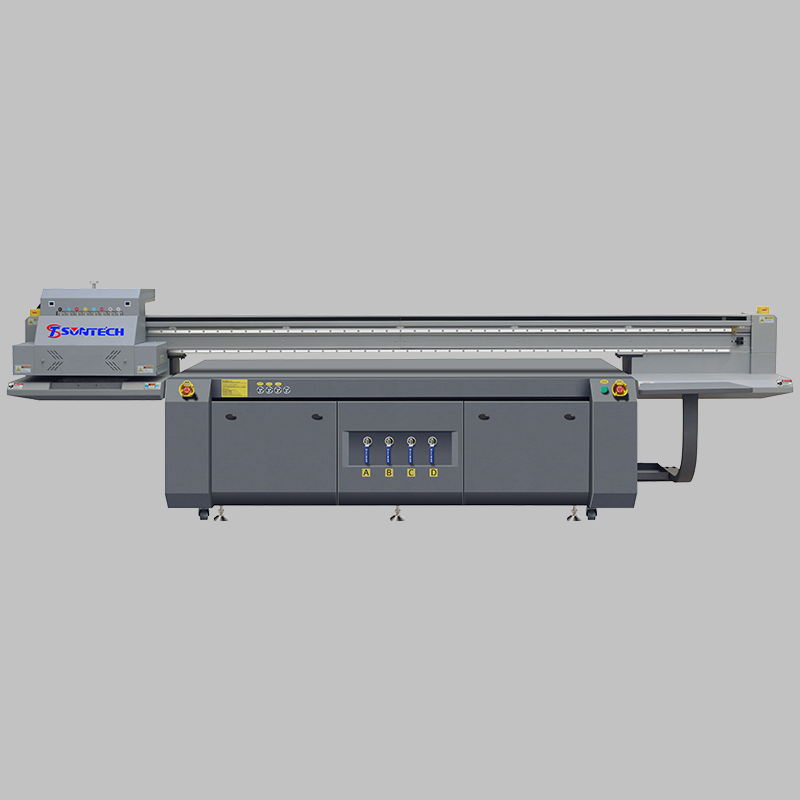

Performance Upgrade, Perfecting the Details

- Epson I1600 Printhead: Featuring precision micro-piezo inkjet technology, each nozzle can finely control ink droplets to ensure impeccable detail reproduction. Whether for intricate graphics or large color areas, the I1600 consistently delivers exceptional color accuracy and image quality, making it perfect for both fine details and broad coverage.

- UV Curable Ink: UV inks are known for their high durability, quick curing time, and minimal environmental impact. The superior UV resistance, water resistance, and abrasion resistance of these inks ensure that printed products retain their vibrant colors even in outdoor or harsh environments. This leads to longer-lasting prints, making it ideal for both indoor and outdoor applications.

- Multi-Function Printing: With support for both flatbed printing and roll-to-roll printing, the 4060UV offers flexible solutions for a wide range of customer needs. The ability to easily switch between print modes enhances versatility, allowing you to handle various material types and improving overall production efficiency.

These upgrades not only enhance 4060UV’s performance but also broaden its application capabilities, making it a powerful solution for businesses seeking high-quality, durable prints across diverse industries.

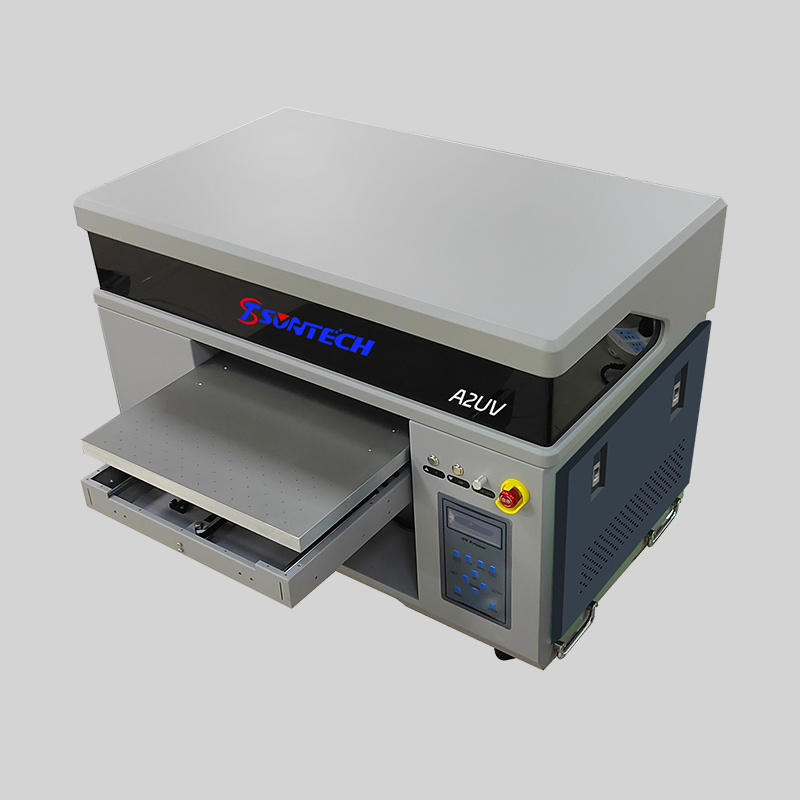

Easy to operate, intelligent control.

The 4060UV is equipped with an efficient intelligent control system, paired with a simple and easy-to-use touchscreen interface, making operation more intuitive and convenient. Even first-time users can master the device’s operation skills in a short period of time. The automatic monitoring system tracks the printing status in real-time, ensuring that each step goes smoothly and minimizing the occurrence of errors.

Introduction to the Core of the Machine

1. Intelligent Ink Supply System — Efficient, Stable, Cost-Effective

The 4060UV flatbed printer’s intelligent ink supply system optimizes ink management with its efficient and precise functionality. This not only reduces ink waste but also enhances overall production efficiency. The system ensures a smoother and more stable printing process, minimizing downtime and the need for manual intervention. Additionally, it helps lower ink procurement costs, allowing users to maintain high product quality while better controlling production expenses. This makes it an ideal choice for businesses looking to improve their competitiveness.

2. Alloy Suction Platform — Outstanding Printing Stability and Precise Positioning

The alloy suction platform of the 4060UV flatbed printer is a key component in ensuring print quality and efficient production. With its powerful suction capability, precise positioning system, and the advantages of alloy material, the platform provides outstanding stability and accuracy for a wide range of printing tasks. Whether it’s large-format printing, handling irregular materials, or high-precision customization, the alloy suction platform delivers consistent and stable printing performance, significantly improving production efficiency, reducing operational costs, and helping businesses maintain a competitive edge.

3. Ink Pushing System — Precise and Efficient Ink Supply Management

The Ink Pushing System, with its precise pumping mechanism, ensures stable ink delivery to the print head, reducing ink waste, balancing ink pressure, and providing automatic cleaning and maintenance. It enhances print consistency and quality, making it a crucial factor in improving both print quality and production efficiency.