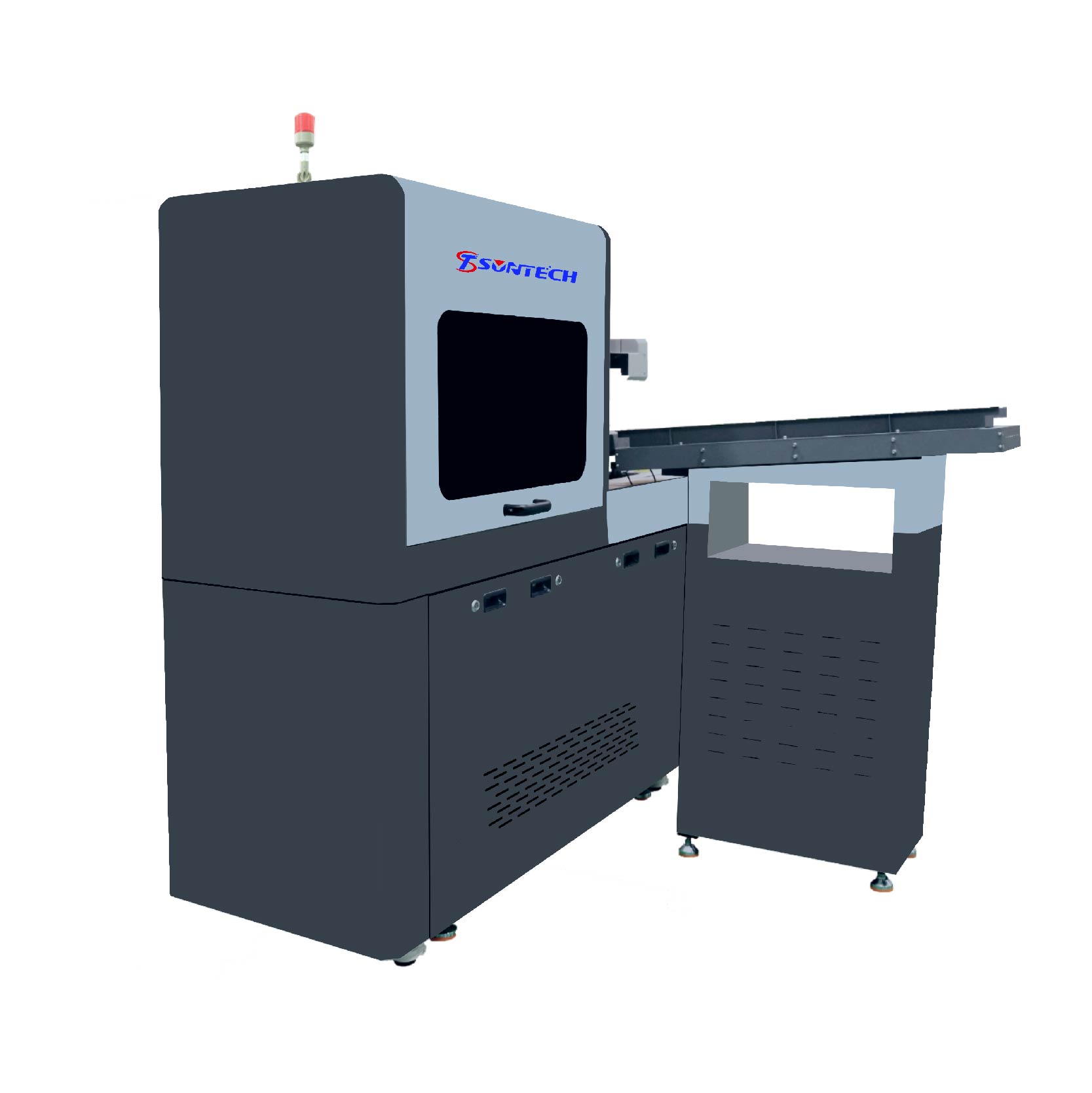

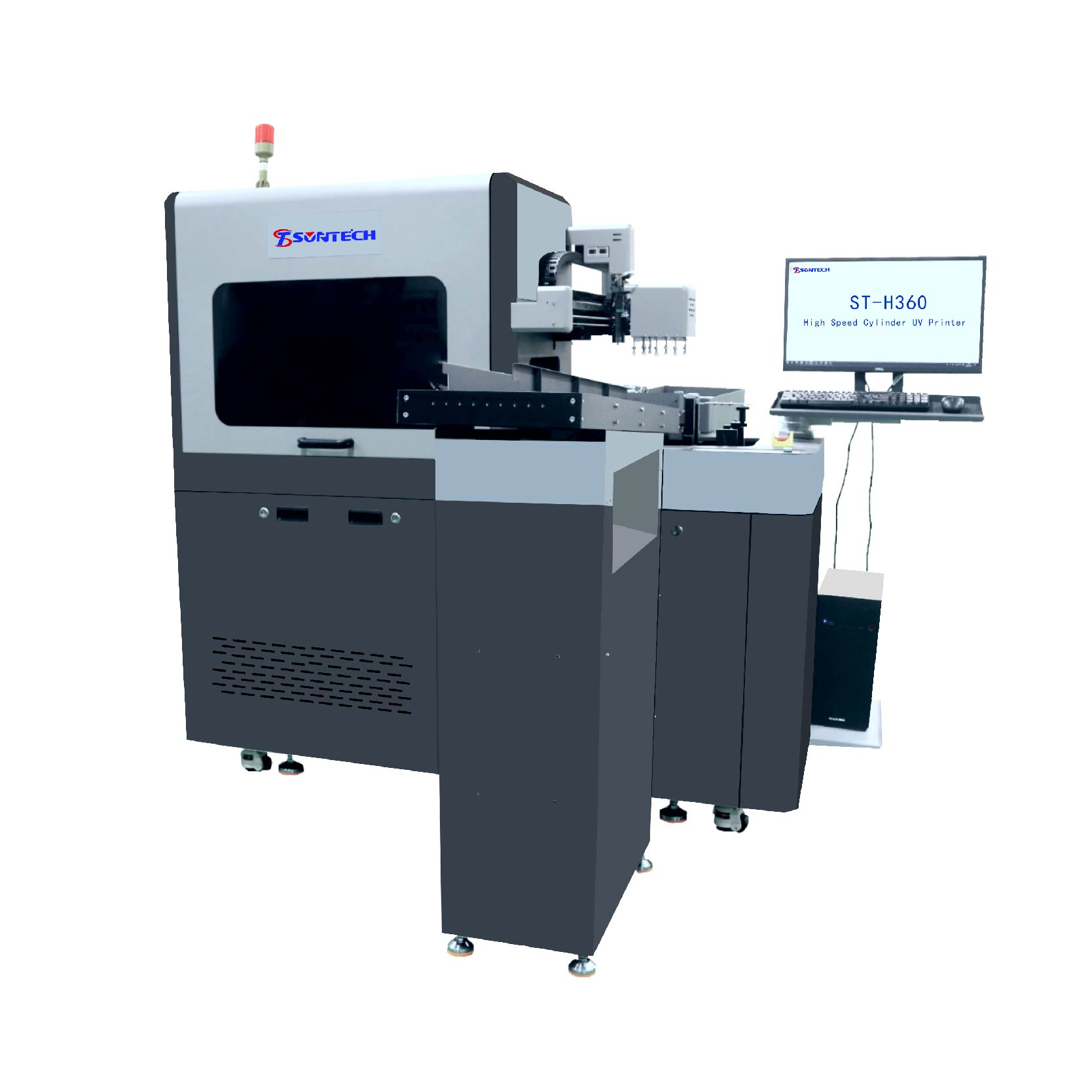

Cylindrical Bottle Printer for Tumblers, Cans, and Water Bottles

This UV Cylindrical Bottle Printer is specifically designed for high-precision color printing on cylindrical materials. It is equipped with the advanced Epson I1600 industrial-grade printhead and supports customized printing for various cylinder specifications. The machine features an integrated automatic loading and unloading system, allowing seamless connection to automated production lines and significantly reducing labor requirements.

The ST-H360E is widely used for personalized printing on items such as water bottles, thermos flasks, glass bottles, egg-shaped cups, tumblers, aluminum cans, and pull-tab cans. With its compact design, stable performance, exceptional printing accuracy, and high efficiency, it is an ideal solution for small to medium-scale customized production.

Key Features

1. High-Precision Printhead: Epson I1600

Equipped with the original Epson I1600 printhead, featuring densely arranged nozzles for high output precision and excellent color reproduction. It offers outstanding durability and stability.

Supports CMYK+W (four-color plus white ink) configuration, allowing simultaneous color and white printing—ideal for dark or transparent materials.

The printhead has a long service life and low maintenance cost, making it suitable for long-term, stable operation.

2. Customizable Printing Sizes

Maximum printing length: 240mm (can be customized for longer lengths upon request)

Compatible printing diameter: Standard is 120mm; customizable within a 50mm–150mm range

Supports a wide variety of sizes to meet the printing needs of most cylindrical products on the market.

3. Synchronized Cylinder Rotation System

High-precision rollers and servo motor control combined with a synchronized rotation mechanism ensure seamless, accurate printing without misalignment or ghosting.

Adjustable clamping mechanism quickly adapts to products of different diameters, enabling fast loading and unloading and improving overall work efficiency.

4. UV Curing System

Equipped with high-energy LED UV lamps for instant curing, enhancing print speed and ensuring strong adhesion.

Cool light source design minimizes heat buildup, protecting materials and extending the lifespan of both the machine and printed products

5 . Compatibility and Operating System

Supports mainstream design formats (e.g., PNG, JPG, TIFF, PDF)

Comes with professional RIP software (e.g., Photoprint, Maintop), allowing easy layout design, color management, and multitasking control

Compatible with Windows 7/10/11 operating systems

Precision Craftsmanship · Every Detail Flawlessly Executed.

1. Automatic loading and unloading.

The automatic loading and unloading function significantly reduces manual intervention and operation time. The printer can automatically complete the entire process of feeding, printing, curing, and unloading without supervision. This automated workflow greatly improves production efficiency, making it ideal for large-scale and continuous production.

2. Dual negative pressure.

The white ink negative pressure is independently controlled, effectively solving the issue of differing viscosity and negative pressure for white ink.

3. Operation Buttons

It is typically used to start, stop, adjust, or switch the operating modes of the device. The design of the operation buttons is simple and intuitive, often accompanied by indicator lights, icons, or text, making it easy for users to understand and operate.

4. Fixture positioning

Fixture positioning refers to the technology or method of using fixtures to accurately position and secure workpieces during processes such as machining, assembly, or printing. The purpose is to ensure that the workpiece maintains an accurate position during the operation, enabling high-precision processing or tasks. Fixture positioning not only improves work efficiency but also ensures product quality, preventing machining errors caused by inaccurate workpiece positioning.

Industry Applications

Coke cup/Children’s Car/Pocket cup/Simmering kettle/Insulated kettle/Egg cup/Beer cup/Coffee cup/Sports water cup/Straight thermos cup, etc.

Technical Support for UV Cylinder Printers

Technical support for UV cylinder printers is essential to ensuring the equipment operates efficiently and stably over the long term. Since UV cylinder printers involve high-precision printing technology, complex hardware systems, and software operations, timely technical support is crucial for users. Below are the common technical support services and content for UV cylinder printers:

1. Installation and Debugging

Equipment Installation: After the equipment arrives at the user’s site, the manufacturer typically provides professional technicians to conduct on-site installation. The technicians will adjust the printer according to the device type and work environment to ensure optimal printing performance.

System Debugging: This includes setting up the operating system, aligning print heads, adjusting the ink system, and installing software. The goal is to ensure the printer runs smoothly in the user’s work environment.

Training Services: Technicians will provide training on how to operate the device, including software settings, material loading, control panel operations, and device maintenance.

2. Print Head Maintenance and Troubleshooting

Print Head Cleaning and Maintenance: The UV print head is one of the most critical components of the UV Cylindrical Bottle Printer. Regular cleaning and maintenance are essential to ensure print quality and extend the equipment’s lifespan. Technical support typically provides cleaning tools and instructions.

Print Head Replacement: If a print head malfunctions, manufacturers can provide a replacement service to resolve the issue quickly and prevent production disruptions.

Troubleshooting: If the device experiences issues such as print quality problems, paper jams, abnormal ink flow, or system crashes, the technical support team will help users diagnose and resolve the problem through phone, remote assistance, or on-site service.

3. Ink System Support

Ink Selection: UV cylinder printers generally use UV curable inks, and different types of printers may require different inks. The technical support team usually offers recommendations for the most suitable ink for the device and helps users select the ink best suited for their applications.

Ink Flow Adjustment: If users encounter ink flow issues during printing, technical support can provide solutions to regulate ink flow and ensure the ink supply system remains stable.

Ink Pipeline Cleaning: Ink sedimentation or blockages in the ink pipeline can affect print quality. Technical support staff will assist in cleaning and maintaining the ink pipelines based on user feedback.

4. Software Support

Software Installation and Configuration: UV cylinder printers typically come with dedicated printing software capable of image design, print path control, color management, etc. Technical support will assist with software installation and ensure compatibility between the software and hardware.

Software Updates and Upgrades: Manufacturers regularly release software updates to improve system performance and address known issues. Technical support personnel will help users with these updates to ensure their equipment is running the latest version of the software.

Image Processing and Adjustment: UV cylinder printers support various image formats. Technical support will assist with image adjustments, resolution settings, and color management to ensure the print results meet the requirements.

5. Operation and Maintenance Manuals

Most manufacturers provide detailed operation manuals and maintenance guides to help users resolve everyday operational issues. These manuals usually include:

Device Operation Workflow: A complete guide on the steps from loading materials to starting the print job, including common settings and adjustments.

Daily Maintenance and Inspection: Regular checks on print heads, ink systems, and drive systems to ensure cleanliness and maintenance.

Troubleshooting Manual: A list of common issues, causes, and solutions to help users quickly address problems.

6. Remote Technical Support

Modern UV cylinder printers often come with remote diagnostic and support features. Users can connect with the manufacturer’s technical support team via the internet if problems arise:

Remote Access: Technicians can access the device’s system remotely to check device status, review log files, and perform system diagnostics.

Real-Time Problem Solving: Technicians can guide users through operations and help solve device faults or optimize print quality.

Remote Software Updates: Software and firmware can be updated remotely to ensure the device’s stability and performance.

7. On-Site Service

For more complex issues that cannot be resolved through remote diagnosis, manufacturers typically offer on-site repair services:

Repair and Replacement: If hardware malfunctions occur, the technical support team will send professional engineers to repair or replace faulty components on-site.

Device Inspection and Maintenance: Regular on-site inspections and maintenance services help users detect potential issues early and perform preventative maintenance.

8. Regular Maintenance and Service Plans

Many UV Cylindrical Bottle Printer manufacturers offer regular maintenance services or service contracts to ensure the long-term stable operation of the equipment. These services typically include:

Regular Inspection and Calibration: Periodic checks and calibration to ensure stable print quality.

Component Replacement: Regular replacement of wear-prone parts, such as print heads, ink pipes, and drive systems.

Priority Response: Users with service contracts can enjoy priority response and quick service support.