High-Performance UV Inkjet Flatbed Printer Machine

A UV Inkjet Flatbed Printer Machine typically consists of a print head, print platform, ink system, and UV curing system. Unlike traditional inkjet printers, this advanced equipment is capable of printing directly on both rigid materials (such as acrylic, glass, wood, metal, plastic, etc.) and flexible materials (such as leather, fabric, etc.). Thanks to its versatility, the UV Inkjet Flatbed Printer Machine is widely used in advertising signage, decoration and interior design, personalized customization, and craft production.

The main working principle of this printer is to spray ink through the print head, which is then cured by ultraviolet light to create high-quality, durable prints. Using the Epson I3200 print head, the UV Inkjet Flatbed Printer Machine ensures high precision, speed, and stability, making it one of the most reliable technologies in the industry.

1. Key Features of the UV Inkjet Flatbed Printer Machine

Precision and Flexibility with Epson I3200 Printhead

The Epson I3200 is a cutting-edge industrial printhead designed specifically for UV ink compatibility. Integrated into the UV Inkjet Flatbed Printer Machine, it guarantees exceptional printing accuracy and fine detail.

-

High Precision: 3200 nozzles with advanced ink control technology

-

High-Speed Performance: Capable of printing up to 16m²/h (depending on material and resolution)

-

Durable and Reliable: Optimized for continuous operation, reducing downtime and maintenance costs

2. Core Advantages of UV Flatbed Printers

A UV Inkjet Flatbed Printer Machine delivers outstanding performance across multiple industries. Its advantages include:

-

Wide Applicability: Ability to print on rigid materials (metal, glass, acrylic) and flexible materials (leather, fabric).

-

High Precision Printing: Supports maximum resolution of 1200×1200 dpi for clear details and vibrant colors.

-

Instant Drying and Durability: UV curing ensures long-lasting, scratch-resistant prints.

-

High Speed and Efficiency: Faster production compared to traditional printing methods.

-

Low Operating Costs: Eliminates costly plate-making and reduces ink waste.

-

Environmentally Friendly: UV inks are VOC-free and safe for various environments.

3. Eco-Friendly UV Printing Technology

The UV Inkjet Flatbed Printer Machine incorporates eco-conscious technology:

-

LED UV Curing: Quick-drying inks cure instantly under UV LED light.

-

Low Power Consumption: Energy-efficient curing system with minimal heat production.

-

Safe and Non-Toxic: UV inks contain no harmful volatile organic compounds (VOCs).

4. Applications of the UV Inkjet Flatbed Printer Machine

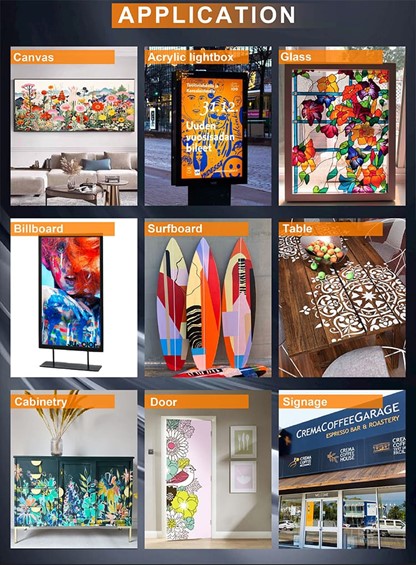

Thanks to its precision and versatility, the UV Inkjet Flatbed Printer Machine can be applied in numerous industries:

-

Advertising: Billboards, banners, outdoor signage

-

Interior Décor: Custom wallpapers, furniture printing, wall art

-

Product Branding: Personalized items, packaging, labels

-

Industrial Use: Direct printing on metal, glass, ceramics, and more

Outstanding Printing Precision · Details Determine Quality

1. Partition adsorption

The zoned vacuum suction system is a key functional module within the platform structure of a UV flatbed printer. Utilizing vacuum adsorption principles, it firmly holds the printing media—such as boards, toy surfaces, and other substrates—securely in place on the print bed.By dividing the platform into multiple suction zones, users can flexibly control which zones are activated based on the size, shape, and position of the material. This design allows for more efficient, energy-saving, and precise printing operations.

2. Printer beam

Ensure the design accuracy of the steel frame and steel beam, steel beam after annealing treatment to eliminate stress, the gantry machine to ensure the design accuracy, steel beam does not deform.

3. Magnetic Levitation

In UV flatbed printers, magnetic levitation technology typically refers to the use of magnetic levitation in the device’s transmission system or certain components to reduce mechanical friction, extend the lifespan of the equipment, and improve the precision and stability of the device.