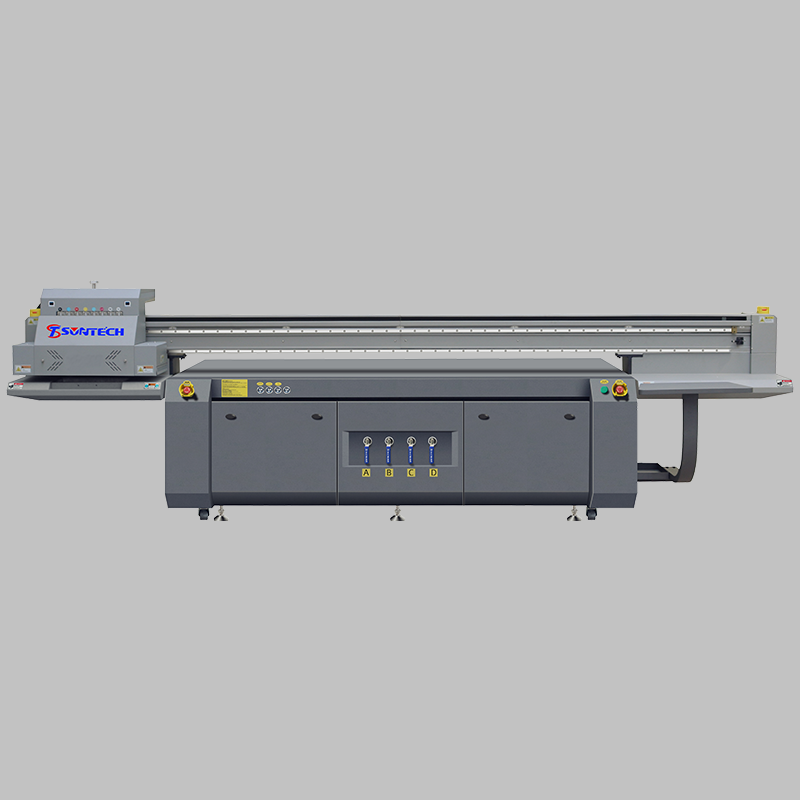

Ricoh Printhead UV Flatbed Printer: High-Precision, Large-Format Printing Solution

Advantages of Ricoh Printheads

1. High Precision

Ricoh printheads utilize piezoelectric inkjet technology, which enables precise control over both the ink droplet size and spray speed. This allows for high-resolution printing that can reach up to 600 dpi or even 1200 dpi in certain high-end models.

The result is incredibly detailed prints that maintain sharpness and clarity, even with complex and fine designs, making it perfect for applications that demand high detail and fine graphic reproduction.

2. Stability and Durability

Ricoh printheads are known for their high durability, making them particularly suited for industrial applications where long-term, continuous use is required.

Their reliable performance ensures consistent results over long print runs, reducing maintenance needs and minimizing downtime. This makes them an ideal choice for industries that rely on high-volume production or 24/7 operations.

3. Advanced Printhead Technology

Ricoh’s printheads are designed with piezoelectric technology, which means each nozzle’s action is controlled by electrical signals. This provides an exceptionally accurate ink delivery system, ensuring that the printheads maintain precision even with rapid or continuous printing.

The flexibility to use a wide range of inks, including UV inks, is another major benefit of Ricoh printheads. This compatibility allows them to handle various ink formulations with consistent quality, making them versatile for multiple types of print applications, whether it’s on flexible or rigid substrates.

4. Efficiency and Speed

Ricoh printheads deliver fast printing speeds without compromising on quality. This makes them highly efficient for large-format printing jobs that require both high speed and high-quality output. Whether for billboards, banners, or packaging, Ricoh’s technology allows businesses to meet tight deadlines while ensuring top-notch print quality.

Common Applications of UV Flatbed Printers

1. Advertising Printing

UV flatbed printers are widely used in producing store signage, advertising banners, and display boards. The ability to print directly on various materials, such as acrylic, PVC, and foam board, makes them ideal for vibrant, long-lasting outdoor and indoor advertising displays

2. Interior Decoration

UV printers can print on a variety of substrates to create unique wallpapers, flooring, curtains, and other home décor items. With their ability to reproduce intricate designs and vibrant colors, UV flatbed printers allow for highly customizable interior decorations.

3. Personalized Products

The ability to print directly onto custom phone cases, business cards, gifts, and souvenirs is one of the key features of UV flatbed printers. This is especially useful for businesses offering personalized products, where individual customization is crucial for customer satisfaction.

4. Art Creation

Artists and photographers often use UV flatbed printers to print artworks or photographs onto various media such as canvas, wood, metal, and glass. This allows for the production of high-quality reproductions of original works or creating new, custom artwork for sale or display.

Attention to Detail, Optimizing Every Aspect

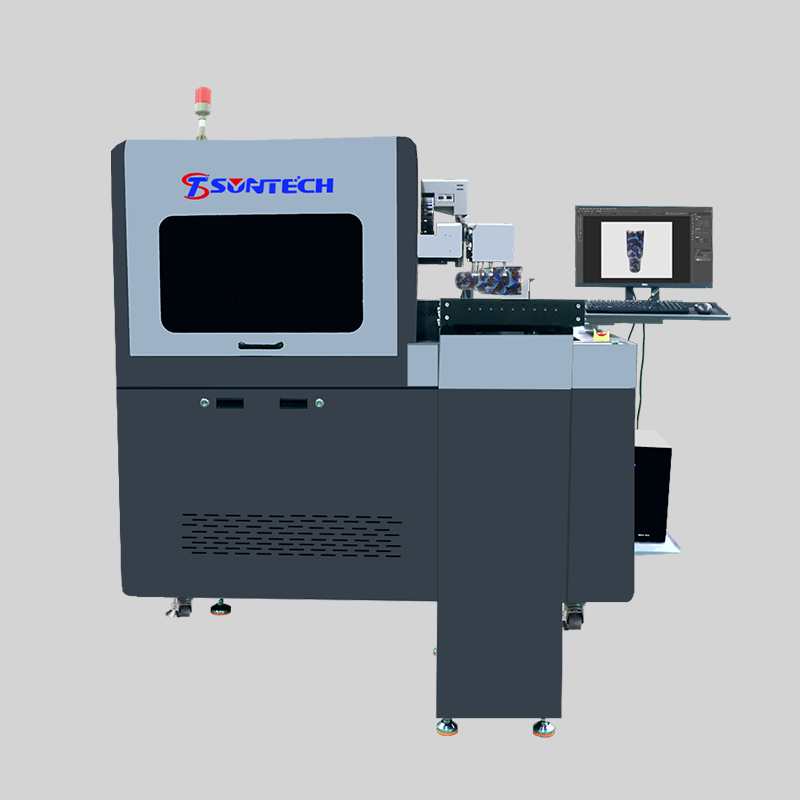

1. Optical Sensing Collision Avoidance System

The integration of UV flatbed printers with a photoelectric collision prevention system enhances safety and intelligence in the automation process. This is especially beneficial for large UV flatbed printers, as the photoelectric collision prevention system helps avoid collisions in complex production environments, preventing damage to expensive equipment and printing media.

2. Magnetic Levitation

- Improved Stability: By using magnetic levitation, it reduces the vibrations caused by traditional mechanical components (such as rails and lead screws), enhancing the printing accuracy and overall stability.

- Finer Control: Magnetic levitation technology allows the printhead to adjust its position with greater precision, preventing vibrations or errors, which is especially crucial in high-resolution printing.

3. Ink Cartridge

An ink cartridge is a container that holds the ink used in a printer. It is designed to be easily replaced when the ink runs out. In the context of UV flatbed printers, the ink cartridges are typically filled with UV-curable inks, which harden when exposed to ultraviolet light. These cartridges come in various colors, including CMYK (cyan, magenta, yellow, and key/black) and sometimes additional colors like white or varnish, depending on the printer’s capabilities.