The quick world of personalization and short-run production has firms always looking for new ways to provide great-looking, high-quality products quickly. One of the technologies that has proved sensational for customized drinkware is the UV DTF printer for cup wraps. This is a state-of-the-art printing solution that combines direct-to-film (DTF) printing with ultraviolet (UV) curing, offering extreme accuracy, strength, and flexibility. For businesses engaged in custom cup or mug, or other beverage container production, choosing a UV DTF printer for their shop can revolutionize an entire production workflow, enhance quality, and add many more creative options.

To understand why a UV DTF printer is best for cup wraps, one must know the technology behind it. Direct-to-film (DTF) print sends bright, high-res designs from a printable film onto the target base. Unlike old ways that might need much prep work or special supplies, DTF lets designs be printed on a film first and then heat-pressed or sent to many types of surfaces later.

When accompanied by UV curing technology, the printed design is immediately solidified and attached to the surface with the use of ultraviolet light. It offers quick drying time with great strength against smudging as well as fading of the print. For curved or irregular surfaces like cup wraps, it guarantees that the ink sticks properly, giving a perfect look at all times.

The Market Context: Why Cup Wrap Printing Matters

The global beverage industry is huge because it consumes billions of disposable as well as reusable cups. Coffee houses, bubble tea chains, and fast-food outlets, down to the level of small artisanal cafés, all compete for share of mind when spending becomes discretionary. Thus, packaging—and more particularly the cup wrap—has assumed major proportions for both branding and customer engagement. Visually attractive cups are much more than just a holder; they also serve as marketing tools, carrying brand identity into consumers’ hands.

Personalization is also driving this demand. Consumers want personalized products that will speak to who they are, commemorate special occasions, or articulate social messages. The faster a business can deliver customized cup wraps, the more likely it is to gain an edge over competitors and make this another source of revenue. UV DTF printing technology was meant for such seamless infusion into creativity and production efficiency.

Key Advantages of Using a UV DTF Printer for Cup Wraps

1. Exceptional Print Quality

One of the primary reasons to choose a UV DTF printer for cup wraps is the unmatched print quality it offers. UV inks provide vibrant colors and sharp details, capturing intricate patterns and fine lines that traditional methods often struggle to reproduce. This precision is particularly valuable for cup wraps, where small graphics, text, or decorative elements must remain clear and readable on a curved surface.

Moreover, UV DTF printers can produce high-resolution prints exceeding 1200 DPI, making them ideal for high-end customized products. Whether the goal is creating promotional merchandise, personalized gifts, or premium retail items, this level of clarity enhances the perceived value of the finished cup.

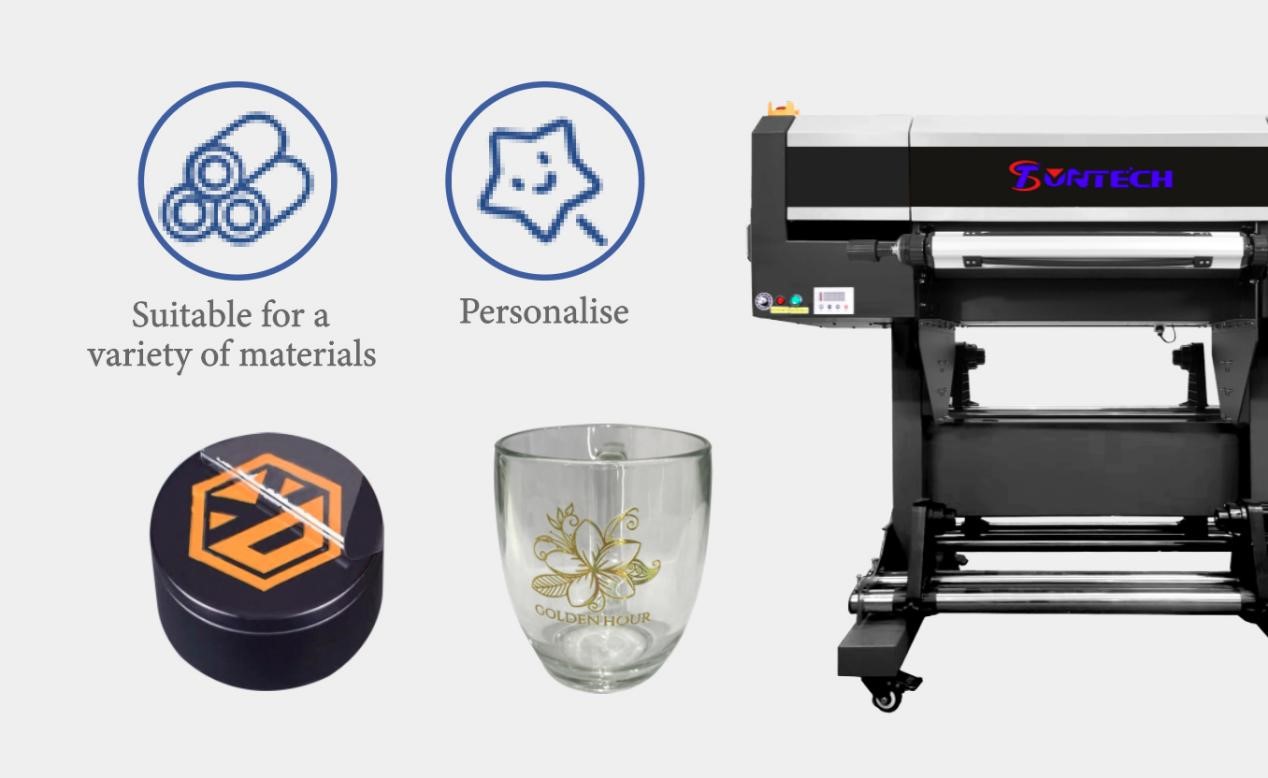

2. Versatility Across Materials

Another standout advantage is the versatility of the UV DTF printing process. Cup wraps come in a variety of materials, including plastic, stainless steel, coated paper, and aluminum, and each requires a printing method that adheres reliably. UV DTF printers are compatible with a broad spectrum of substrates, ensuring consistent adhesion and color fidelity across diverse surfaces. This capability eliminates the need for multiple machines or separate printing processes for different materials, streamlining production and reducing equipment costs.

3. Durability and Longevity

Products that experience frequent handling, washing, or exposure to liquids require a printing method that ensures long-term durability. UV DTF printing achieves this by curing the ink with ultraviolet light, forming a tough, protective layer over the design. The result is a print that resists scratching, fading, and peeling, maintaining its vibrant appearance even after repeated use. For cup wraps, this durability is crucial, as it ensures that the design remains intact and visually appealing for the life of the product.

4. Speed and Efficiency

Efficiency is a critical factor for businesses looking to scale production or respond quickly to custom orders. UV DTF printers offer fast printing and instant curing, which significantly reduces production time compared to traditional screen printing or sublimation methods. There is no need to wait for ink to dry or undergo multiple stages of processing, making it ideal for high-volume orders or last-minute customization requests.

Additionally, because the design is printed onto a film first, the process allows batch production and easy inventory management, enabling companies to keep pre-printed designs ready for rapid transfer onto cups as needed.

5. Cost-Effectiveness for Small and Large Batches

Unlike some printing methods that are only cost-effective at large volumes, UV DTF printing is highly economical for both small and large batch production. Businesses can print limited editions, seasonal designs, or promotional items without incurring excessive setup costs. At the same time, scaling up for mass production is seamless, as the process can accommodate high-speed printing and repeated transfers with minimal waste.

6. Creative Freedom and Customization

UV DTF printers provide remarkable creative flexibility. Full-color images, gradients, logos, and intricate patterns can all be rendered accurately, allowing brands to deliver truly unique cup wrap designs. Designers are no longer constrained by substrate limitations or complex setup requirements, enabling experimentation with textures, finishes, and multi-layered effects.

Personalized products, such as cups with customer names, event logos, or themed artwork, become easy to produce. The combination of precision, durability, and vibrant colors ensures that each product feels premium and high-quality, which is particularly important in the personalized merchandise market.

Comparing UV DTF with Traditional Printing Methods

To better understand the value of UV DTF printers, it is important to compare them with older technologies:

-

Screen Printing: Widely used for cup printing, but requires extensive setup, screens for each color, and is less suitable for small runs. Complex designs are difficult to reproduce accurately.

-

Sublimation Printing: Works well on coated surfaces but is limited in terms of material compatibility. It often requires specific coatings and cannot achieve the same durability as UV curing.

-

Vinyl Stickers or Labels: Easy to apply but prone to peeling, scratching, and fading over time. They also lack the premium feel of a directly transferred print.

In contrast, UV DTF combines the strengths of each while eliminating many drawbacks. It delivers high-quality, durable prints across multiple substrates, all with greater efficiency.

Applications of UV DTF Printers for Cup Wraps

The versatility of UV DTF printers makes them suitable for a wide range of applications:

-

Promotional Merchandise: Custom-branded cups for marketing campaigns, trade shows, or corporate gifts.

-

Retail Products: Unique designs for boutique coffee shops, gift stores, or beverage companies.

-

Personalized Gifts: Custom cups for birthdays, weddings, anniversaries, or special occasions.

-

Limited Edition Collections: Seasonal or event-specific cup designs for collectors or enthusiasts.

-

Brand Packaging: Cup wraps that enhance the aesthetic appeal of product packaging while providing brand visibility.

By adopting a UV DTF printer, businesses can expand their product offerings, cater to niche markets, and differentiate themselves from competitors.

Shenzhen Suntech Digital Equipment Co., Ltd. A Leader of the New Wave of UV Printing.

- Just as much as the technology itself, one should always consider who is supplying it when evaluating UV DTF printers. What better global leader in the field of UV printing solutions could there be than Shenzhen Suntech Digital Equipment Co., Ltd.? The company comes to us from a realm of high-tech enterprises where they have specialized in R&D, manufacturing, and exporting top-quality UV printing equipment while steadily building up their reputation for innovativeness, quality products, and excellent customer support.

- Commitment to research and development, as well as continuous innovation, Suntech runs an indoor laboratory of minds responsible for improving UV printing technology. Engineers there continuously create high-performance intelligent multi-functional printers to satisfy market needs. When you buy from Suntech, you are buying the latest fruits of investment in research and development, thereby keeping yourself ahead in innovation.

- Suntech practices the ISO 9001 quality management system at the levels of its operations. From raw material to final shipment, every stage is controlled under a very strict system. This stringent control ensures that the machine will perform the actual function it was bought for stably and reliably over a long service life.

- The firm applies progressive CNC machining centers, laser cutting machines, as well as automatic coating lines to keep exactness at all stages of production. Every part and final amalgamation is made with keen tolerances, resulting in top quality plus strength. This careful method makes sure that Suntech printers give great output in actual use situations.

- Realizing the importance of after-sales service, Suntech has thrown in comprehensive warranty programs plus 24/7 technical support. This can help a business reduce any form of downtime, keep the workflow optimized, and maximize the return on investment.

Factors to Consider When Choosing a UV DTF Printer

Selecting the right UV DTF printer for cup wraps requires careful consideration of several factors:

-

Print Size and Resolution: Ensure the printer can handle the maximum size of your cup wraps and provide sufficient DPI for high-quality designs.

-

Ink Compatibility: Verify that the printer uses UV inks suitable for your target substrates.

-

Curing System: Check the efficiency and reliability of the UV curing module, as it directly affects print durability.

-

Ease of Use: Look for printers with user-friendly interfaces, software support, and easy maintenance to reduce downtime.

-

Cost of Operation: Consider not only the initial investment but also the ongoing cost of inks, films, and maintenance.

-

Customer Support: Reliable technical support and training are critical for smooth operation and troubleshooting.

Evaluating these aspects ensures that the printer meets both current production needs and long-term business growth plans.

Trends and Future Developments

The market for customized cup wraps is growing rapidly, driven by consumer demand for personalized and aesthetically appealing products. UV DTF printers are at the forefront of this trend, with several emerging developments:

-

Automation: Integration with robotic arms and conveyor systems for fully automated cup wrapping and printing.

-

Eco-Friendly Inks: Advancements in UV-curable inks that are environmentally friendly and safe for food-contact surfaces.

-

Enhanced Substrate Compatibility: Printers capable of handling more complex materials, including textured or flexible wraps.

-

AI-Powered Design Tools: Software enhancements that streamline customization by automatically generating or adjusting designs for different cup sizes.

-

Higher Speed and Resolution: Newer models achieve faster throughput without compromising print quality.

These innovations are making UV DTF printing an increasingly attractive option for businesses looking to stay competitive in the customization market.

Choosing a UV DTF printer for cup wraps offers a unique combination of efficiency, quality, and creative freedom. By providing high-resolution, durable, and vibrant prints, this technology allows businesses to deliver premium, customized drinkware that stands out in the market. Its versatility across materials, speed, cost-effectiveness, and ease of use make it an indispensable tool for both small-scale artisans and large-scale manufacturers.

As consumer demand for personalized and eye-catching products continues to rise, investing in a UV DTF printer ensures that your business can meet expectations, expand product offerings, and maintain a competitive edge. Whether for promotional merchandise, retail products, or unique gift items, UV DTF printing is revolutionizing the cup wrap industry, enabling brands to combine innovation, reliability, and style in every printed product.

By partnering with an experienced manufacturer like Shenzhen Suntech Digital Equipment Co., Ltd., companies can take full advantage of these opportunities, ensuring access to cutting-edge technology, reliable performance, and world-class support. In an era where customization defines success, a UV DTF printer is more than just a tool—it is a strategic investment in growth, creativity, and market leadership.