Detailed Explanation of UV Cylindrical Printers Using Ricoh Nozzles

UV cylindrical printers are specialized devices designed for high-precision printing on the surfaces of cylindrical or curved objects, such as bottles, cups, metal tubes, cosmetic containers, etc. UV cylindrical printers equipped with Ricoh series nozzles have occupied an important position in the industrial printing field due to their high precision, high speed and stability.

The core advantages of Ricoh nozzles

The application of Ricoh nozzles (such as Ricoh Gen 5, Gen 6, etc.) in UV cylindrical printers mainly relies on the following technical advantages:

- High resolution & high precision

Minimum ink droplet size: 3.5-7 picoliters, capable of achieving an ultra-high resolution of 1440dpi to 1600dpi, suitable for fine patterns and gradient colors.

Variable droplet Technology (VSD) : It can dynamically adjust the droplet size (such as 3.5pl/7pl/14pl), optimizing the printing speed and accuracy.

- High printing speed

Multi-level grayscale printing (8 to 16 levels of grayscale), reducing the number of passes (the number of layers in a single print), and improving production efficiency.

The maximum spray frequency can reach 50kHz to 100kHz, and the printing speed of industrial-grade models can reach 30 to 60 meters per minute (depending on the material).

- Stability and durability

Industrial-grade nozzle design, supporting 24/7 continuous production, with a long service life (usually 2 to 3 years).

Resistant to UV ink corrosion, suitable for UV curing ink, and not prone to clogging.

- Multi-color printing capability

Supports CMYK+ white ink + varnish (6-color or 8-color configuration), achieving high color gamut and special effects (such as 3D embossing, local varnish).

2. Applicable materials and application fields

- Applicable materials

Plastics: PET bottles, PVC pipes, cosmetic bottles, toys, etc.

Glass: wine bottles, perfume bottles, glass cups, etc.

Metals: aluminum cans, thermos cups, metal pipes, etc.

Ceramics: mugs, tiles, handicrafts, etc.

- Main application industries

Packaging and printing: Personalized customization for beverage bottles, cosmetic packaging, medicine tubes, etc.

Home decoration: cylindrical vases, lampshades, pen holders, etc.

Industrial parts: metal pipe marking, electronic component printing, etc.

Promotional gifts: Customized water cups, souvenirs and other small-batch production.

3. Maintenance and optimization suggestions

Nozzle maintenance: Daily automatic cleaning to prevent UV ink from curing and clogging.

Environmental control: Maintain a constant temperature (20-28℃) and humidity of 40% – 60%.

Ink selection: Use original or certified UV ink to avoid damage to the nozzle from inferior ink.

Regular calibration: Adjust the nozzle height and ink drop point through software to ensure printing accuracy.

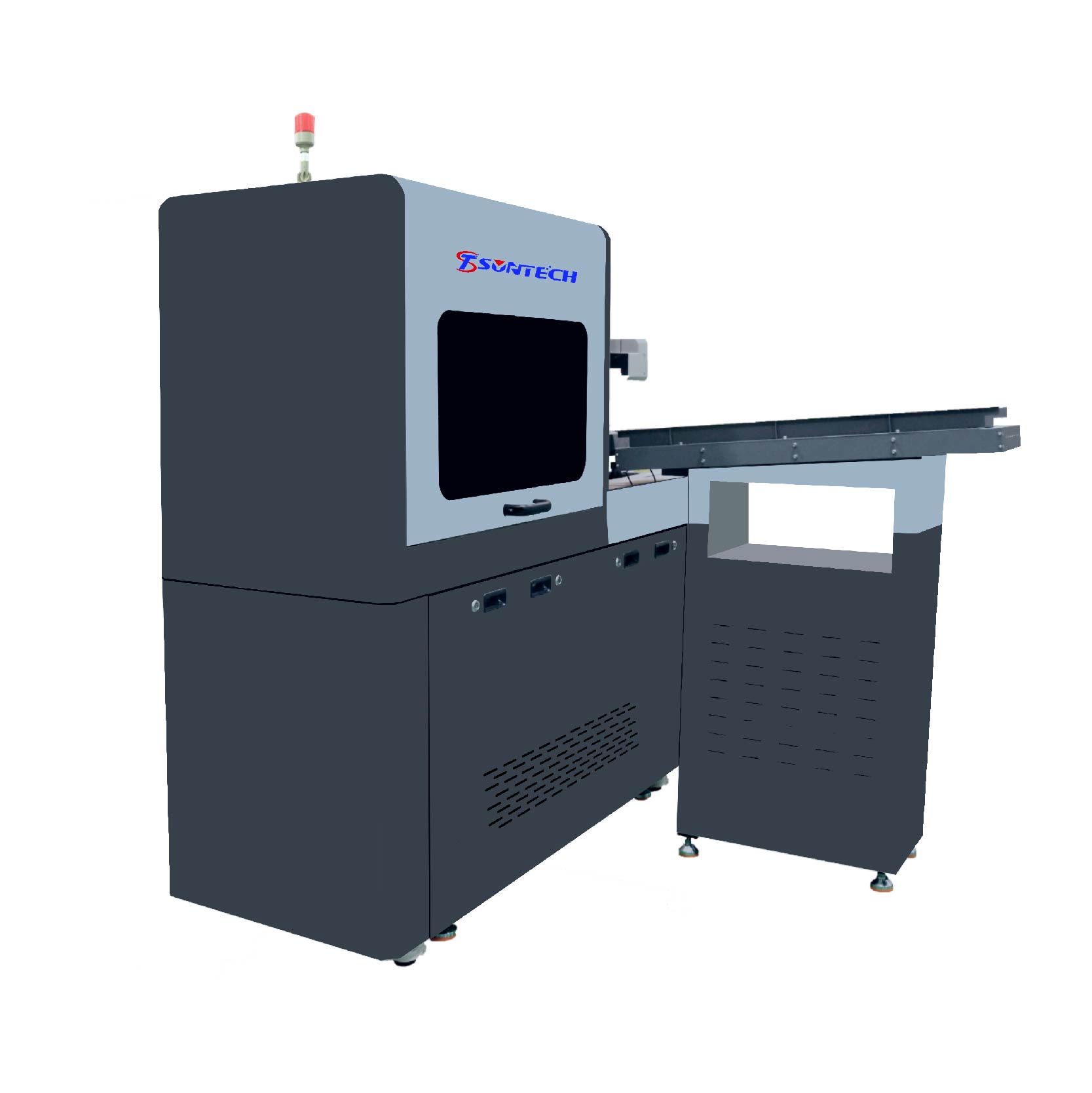

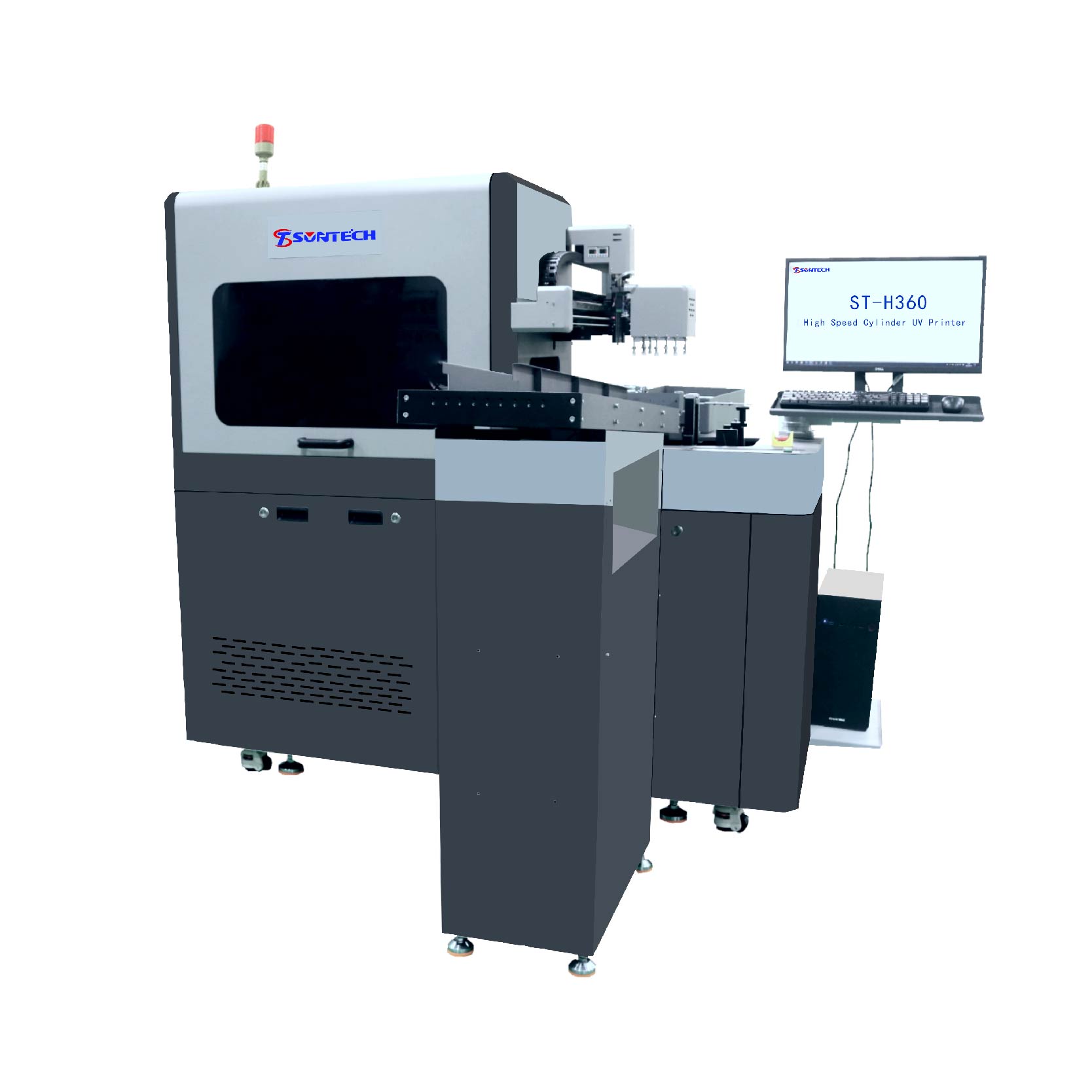

ALL YOU NEED TO KNOW ABOUT OUR ST-H360R UV PRINTER

1.Print on Various Special Surface With the right jig,you can print on cylindrical,tapered and conical objects.

2.Offer Fast Printing Speed and Stable Production The high printing speed is as fast as 30 seconds per piece,great fit for mass production.

3.Make Huge Profist by Customizing High-value Items Handle bottles ranging in length from 80mm to 240mm,print Diameter Maximum 120mm(Customizable),which can meet the needs of various types of products such as tumblers,travel mugs,beverage bottles,vacuum water bottles etc.

4.Print ac-curacy up to 2400dpi.Make it easier to access superb and ex-quisite printing quality,highly restore vivid image.

5.High Droplet Printing Creates More Custom Items Supports 2-13mm high droplet printing,and the laser automatically measures the product shape to achieve precise positioning and easily and perfectly print custom dimensional objects.Full color,gradients,texture,variable data like names/numbers,and seamless full wrapsare easily achievable.

6.Easy to Operate and Understand The multi-diameter cylindrical jig enables to meet the printing needs of a variety of products.The bottle adjusting jig is equipped with scale adjust-ment

Quality service

1. Troubleshooting

Scope of services committed in accordance with the contract; The company sent after-sales engineers to troubleshoot the problem and resume normal production as soon as possible;

2. Service Tracking

Regularly take the initiative to visit customers; Understand the use of equipment, listen to customer suggestions and give technical guidance, and make records;

3. Service Consulting

The professional engineer after-sales service team adopts a variety of service methods to provide 7*24 hours Full-time online service;

4. Service Guarantee

The equipment comes with a one-year free warranty and lifetime maintenance service according to the standard.