Hot Selling UV Cylinder Printer Machine for Wood, Acrylic Metal

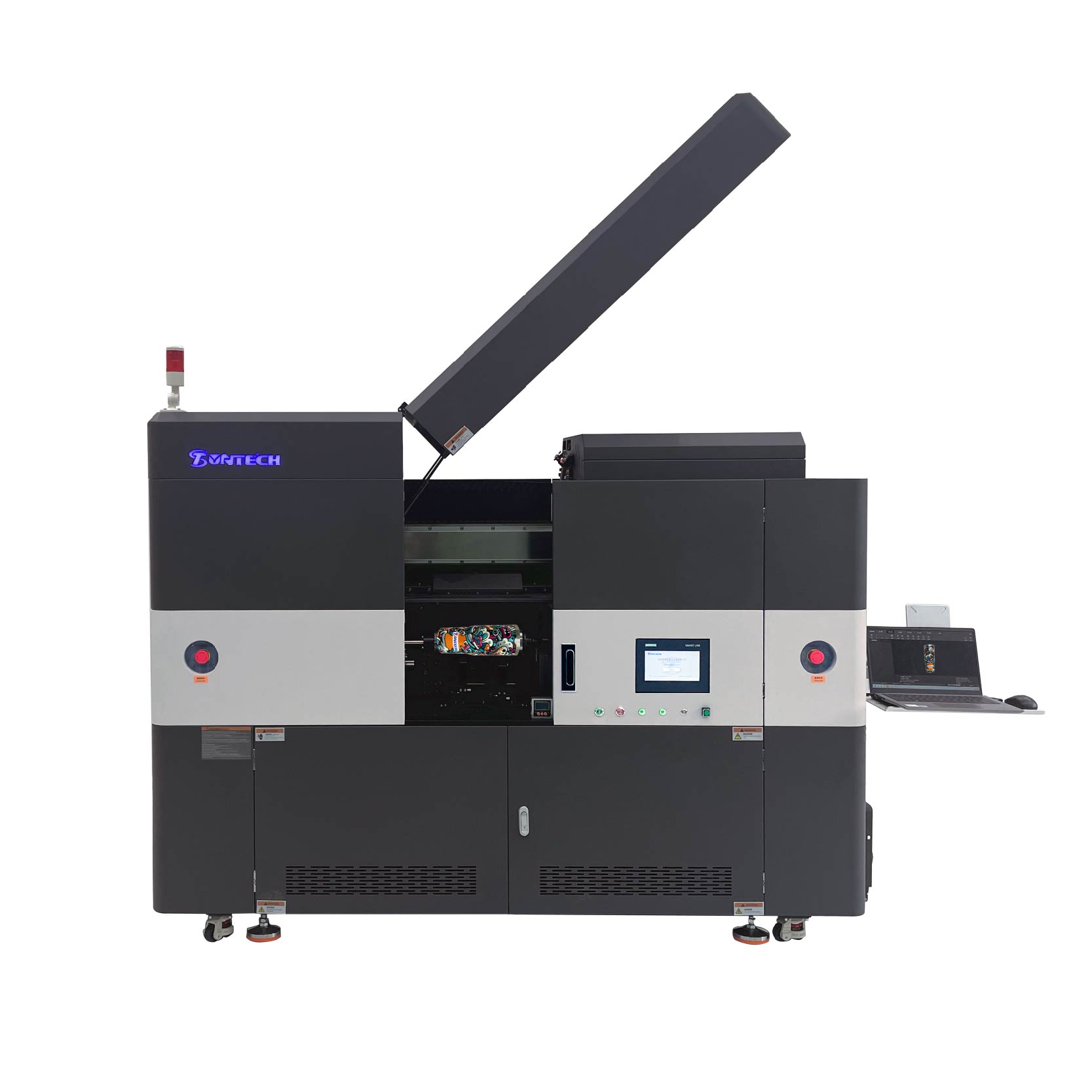

This advanced UV cylinder printer machine features a flip-top design and Toshiba CF3 industrial printheads, delivering high-speed, high-precision printing for bottles, cups, tubes, and other cylindrical objects. Ideal for cosmetics, beverage, and promotional product industries.

Key Features & Technologies

1. Flip-Top Design

Quick-access chamber for effortless loading/unloading

Enhanced safety with a magnetic locking mechanism

Reduced downtime during substrate changes

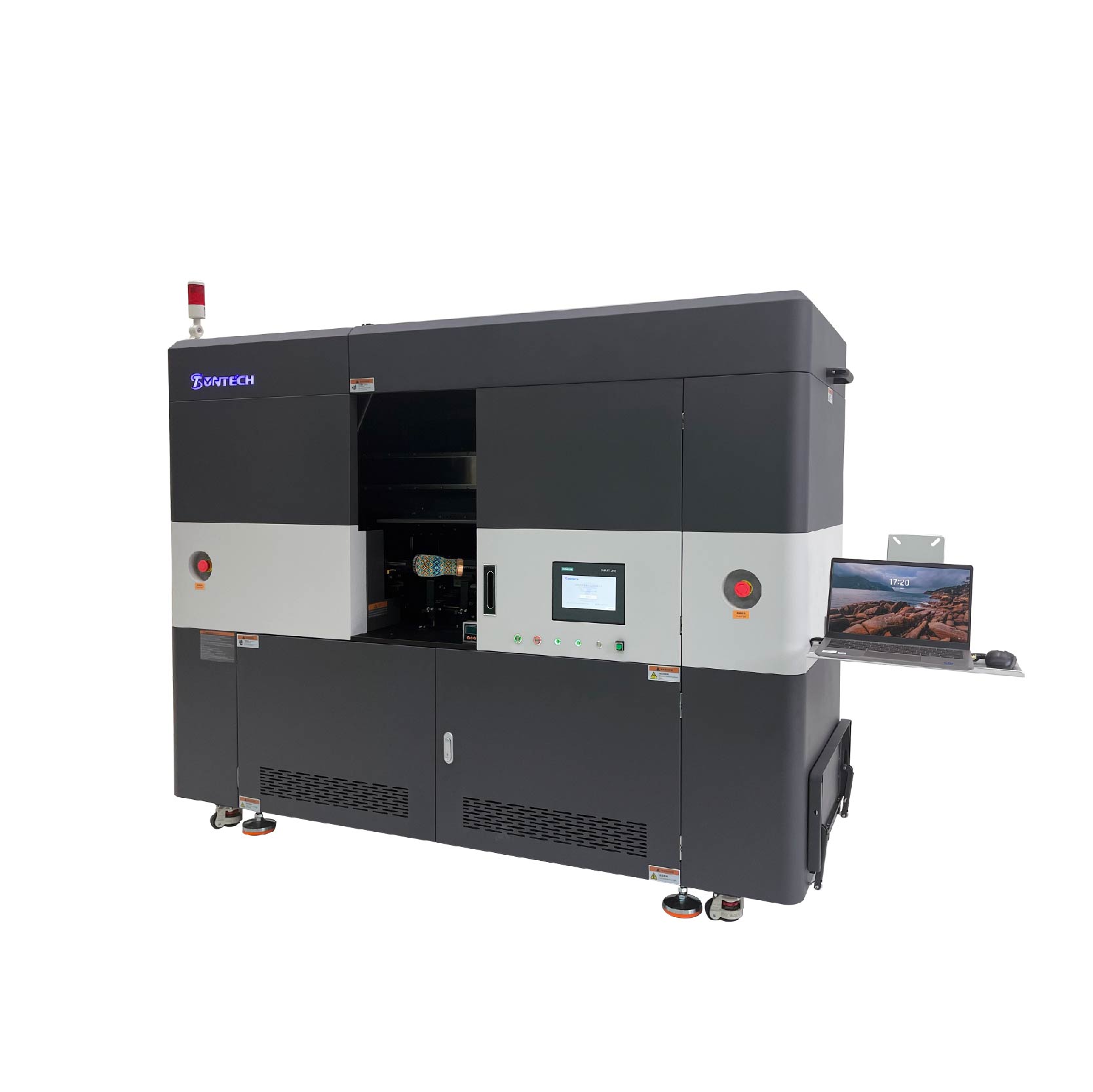

2. Industrial Control System

Siemens PLC + 10″ Touchscreen

Real-time monitoring of printing parameters

Preset 100+ material profiles (glass, metal, PET, etc.)

Error alerts with troubleshooting guides

3. Toshiba CF3 Printhead Advantages

15kHz firing frequency → 35% faster than Gen5 piezoelectric heads

6-level variable droplets (3-21pl) → Optimized for both fine text & solid fills

Auto-cleaning & humidity control → 72-hour standby without nozzle clogging

4. Smart Modeling & Alignment

Laser-assisted auto-modeling

Scans cylinder diameter/length in <15 seconds

Mirror-assisted printhead inspection

Visual confirmation of nozzle conditions

Minimizes manual checks (saves 5+ min/hour)

Detailed product information of the UV Cylinder Printer Machine

1. Real-time data display and feedback of inclination angle, more accurate and convenient

The inclinometer with real-time data feedback has been added, and the operator no longer needs to visually confirm whether it is parallel to the printhead base plate, making it easier and faster to print conical products.

2. Automatic modeling

Using ultra-small laser displacement sensors, it is easy to achieve ultra-high

precision modeling, and seamlessly achieve the modeling and printing of various

special-shaped bottles.

3. Use Siemens key electrical equipment to ensure system stability

The key control components utilize Siemens PLC and a touch screen to ensure the stable operation of key equipment in the system.

4. High-strength spring

Using a high-strength spring, it adapts to the slight errors brought by the same product bottles between production, and the clamping of the bottle has a buffering effect, reducing the impact of the clamp on the bottle.

5. Double-layer suction flying ink device, filter, and purify discharge

Reduce flying ink pollution

Install a large suction exhaust device to absorb ink in two directions at the same time to reduce the spread of ink.

6. Install a reflector to easily observe the surface status of the printhead

Install a reflector at the moisturizing position to easily observe the surface status of the printhead at any time.

7. Automatic height measurement function

According to the different sizes and diameters of the bottles, one-button height measurement can be performed after adjusting the fixture, which is convenient for operation.

8. Designed for use with light inks for richer print and better picture quality

In addition to the basic configuration of white, color and glossy oil, it can support up to 4 kinds of light inks (add 2 nozzles) (light blue LC, light magenta LM, light yellow LY, light black LK), or optionally support 2 kinds of light inks (add 1 nozzles) to meet the requirements of high image quality

9. The machine head moves with a high-precision linear module,

with a repeatable positioning accuracy of 0.01mm

Using a high-precision module, the machine head moves smoothly, with high

positioning accuracy and guaranteed image quality.

10. Automatic printhead cleaning and moisturizing function

Scraping is completed automatically, reducing the number of operating steps and the probability of misoperation. At the same time, it is equipped with a moisturizing device to reduce the risk of printhead blockage caused by long-term shutdown during holidays and extend the service life of the printhead.

Industry application of UV Cylinder Printer Machine

Thermos cup and pot industry: Car cup/Coke cup/Children’s cup/Pocket cup/Simmering kettle/Insulated kettle/Egg cup/Beer cup/Coffee cup/Sports water cup/Straight thermos cup, etc.

Why did you choose us?

1、Perfect after-sales service

With an after-sales team of over 10 people, we offer 7×24-hour multilingual technical support to ensure that your issues are responded to within 30 minutes and resolved within 48 hours. No matter where you are, we can provide remote diagnosis or on-site services.

2、Quality assurance

The designer has 20 years of experience. Product quality assurance and customer customization are provided. Imported accessories are used

Inside the equipment Standardized production operation process

3、Sold overseas

All machines pass the CE and FDA certificates. With the United States, Australia, Europe, and Southeast Asia waiting for cooperation with customers in more than 100 countries and regions